WATER MANAGEMENT EXPERTS

Get in touch on 1800 092 210

Completed Projects

Completed Projects

28 Mar, 2024

PROJECT Upgrade of the existing integrated water management system. INDUSTRY Mining LOCATION Lithgow, NSW Australia EQUIPMENT Centrifugal Pumps and Pump Motorset 4 x Demountable mobile pump buildings 2 x Complete switchrooms DURATION 12 months VALUE $5.5 Million DESCRIPTION Aqua Energy Group were chosen to design, supply, and construct a water management system in Lithgow, Australia. This included an upgrade of an existing water management system, demountable pump buildings and two complete switchrooms. Aqua Energy Group managed everything from civil works through to final commissioning and hand over of the project. CHALLENGES Aqua Energy Group was able to navigate very tight environmental requirements and a tight timeframe. Dewatering was operational throughout the entire project.

21 Mar, 2024

PROJECT Modular Fire Pump Station INDUSTRY Mining LOCATION Mt Thorley EQUIPMENT Complete modular fire pumpstation including diesel hydrant booster, electric hydrant booster and Cummins engine. All associated interconnecting pipes and electrical work were supplied. DURATION 12 months DESCRIPTION Aqua Energy Group were engaged to design, supple, install & commission a complete modular fire pumpstation in Mt Thorley NSW. All civil, electrical, and mechanical requirements were met to ensure the package was in line with MDG15 standards. CHALLENGES Aqua Energy Group ensured the fire pump station adhered to strict mining standards.

21 Mar, 2024

PROJECT Modular Fire Pump Station INDUSTRY Mining LOCATION Hunter Valley, NSW Australia EQUIPMENT 1x complete modular fire pumpstation 2x large 500kL storage fire water tanks and all associated piping and electrical works. DURATION 9 months VALUE $1 Million DESCRIPTION Aqua Energy Group were engaged to design, supply, install and commission a complete turnkey fire protection plant for the UG coal mining industry. This project incorporated the complete design, supply and installation of all equipment according to MDG15 requirements. CHALLENGES Aqua Energy Group was able to navigate very strict environmental requirements, an operational mine site, and a tight timeframe.

21 Mar, 2024

PROJECT Modular Fire Pump Station INDUSTRY Mining LOCATION Appin, NSW EQUIPMENT SUPPLIED Complete modular fire pumpstation fitted with diesel hydrant booster, electric hydrant booster and Cummins engine. All associated interconnecting pipework and electrical works were also supplied. DURATION 9 months VALUE $5 million DESCRIPTION Aqua Energy Group were engaged to design, supply, install & commission a complete modular fire pump station for South32 in Appin, NSW. All civil, electrical, and mechanical requirements were met to ensure the fire pump package was in line with MDG15 standards. This fire pump system was part of a major project in this mine consisting of a sewage treatment plant, potable water tanks, and fire water tanks. Pumps and reticulation equipment was also supplied. CHALLENGES Aqua Energy Group worked within a tight timeframe to ensure the customer received their fire pump station rapidly. Strict mining standards were adhered to for the duration of this project.

06 Mar, 2024

PROJECT Tekapo Remediation INDUSTRY Infrastructure LOCATION Tekapo, New Zealand EQUIPMENT 13 No. 30m@1500L/S Pumps, 13 No.60m @400L/S Pumps DURATION 6 Months VALUE $4 Million Aqua Energy Group Partnered with our client to design, supply and install a mobile fully automated and generator powered pumping system for canal remediation in the remote area of Tekapo, New Zealand CHALLENGES Remote Location with no national grid power or communication service available. Short programme. Critical national infrastructure project.

06 Mar, 2024

PROJECT Modular Fire Pump Station INDUSTRY Mining LOCATION Central West, NSW Australia EQUIPMENT 1X complete modular fire pumpstation, 2 X large 500kl storage fire water tanks & all associated interconnecting Pipework & Electrical works DURATION 9 months VALUE $1 Million Aqua Energy Group were engaged to design, supply, install & commission a complete Turn-Key Fire Protection Plant for the UG Coal Mining Industy. This Project incorporated the complete Design, Supply, Installation and Commissioning of this package which incorporated a complete modular fire pumpstation & Water Supply Pumpstation and incorporated the supply & installation of 2 X 500KL Fire Water Tanks , all civil requirements, all Electrical Requirements, and all mechanical requirements to facilitate a complete Turnkey package all to MDG15 Requirements. CHALLENGES Aqua Energy Group was able to navigate very strict environmental requirements , an operational mine site and tight timeframe for the customer to get their new UG Fire Water Modular Booster Pumpstation up and operational.

06 Mar, 2024

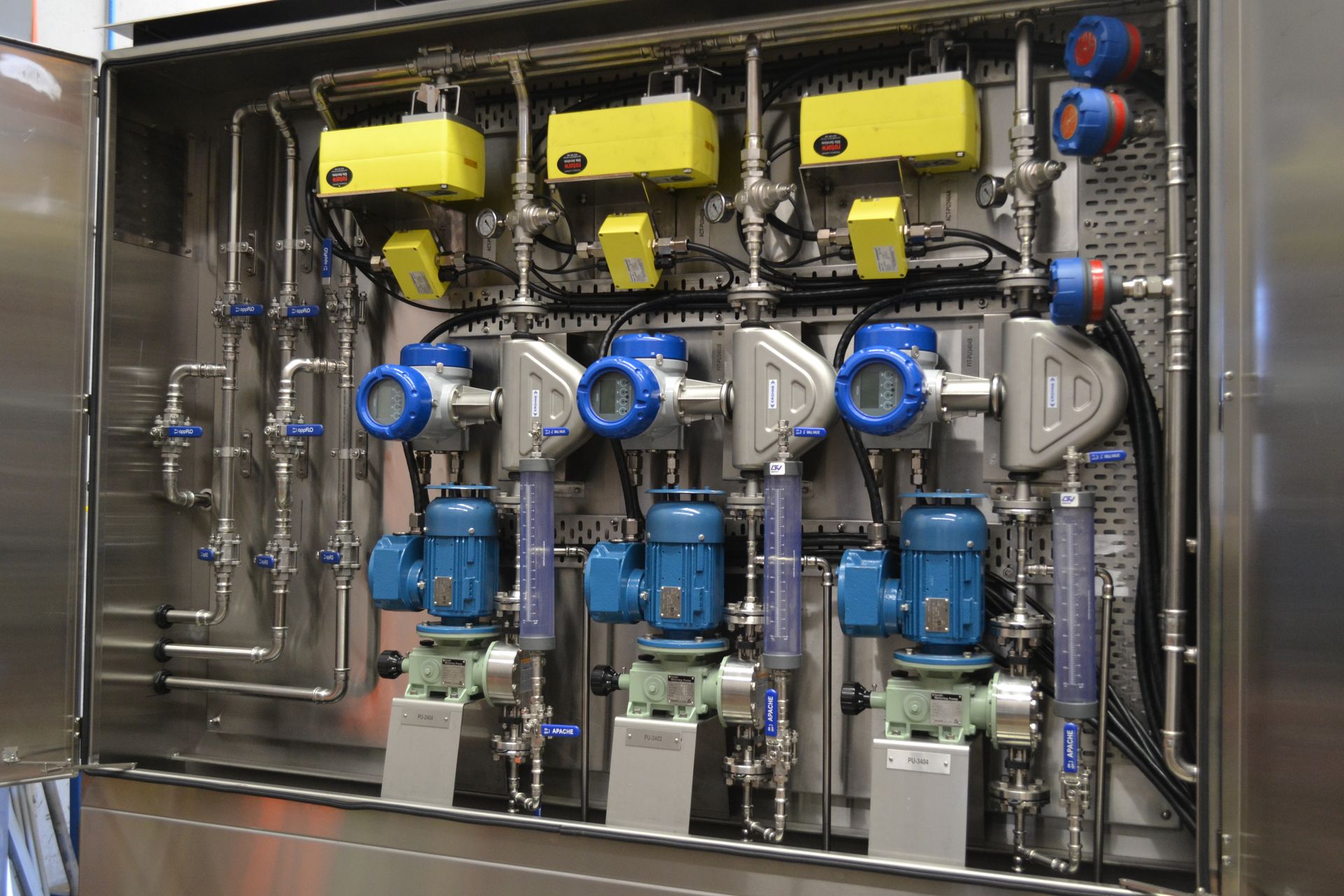

PROJECT Reagent Turnkey Dosing Station INDUSTRY Mining LOCATION Hunter Valley, NSW Australia EQUIPMENT 2x Double- sided, Custom Designed dosing pump cabinets for hazardous and Non-hazardous fluids, 1x motor Control cabinet DURATION 9 months VALUE $1 Million Aqua Energy Group were engaged to design, supply, install & commission a complete Reagent Plant to suit our clients requirements. This Project utilises two double sided pump cabinets with a mixture of hazardous–rated and standard dosing pumps to pump set amount of liquid into the thickening plant on site. These cabinets are accompanied by a customised switchboard for full operation of the units. Two large 40FT containerised Fuel storage units were supplied as part of our package, flow-monitoring, all lighting, and complete installation project. CHALLENGES Aqua Energy Group was able to navigate very strict environmental requirements and tight timeframe for the customer to get their new coal fines handling plant up and operation ASAP.

05 Mar, 2024

PROJECT NSW Water Utilities Drought Relief INDUSTRY Infrastructure LOCATION Inland, NSW Australia EQUIPMENT Containerised Switch rooms, 415V MCC, 2 x pontoons, 6xpumps @660L/s each Pump, Pipelines/ Valving DURATION 6 months VALUE $3.8 Million The Project Included the Design, supply, and delivery of two pontoons delivering up to 300ML a day of Freshwater to a coffer dam arrangement. The Project also consists of a 415V Containerised Switch room, heavy-duty trailing cable, and a flexi DN600 pipeline arrangement for the two pontoons. This project was a full D&C by the Aqua Energy Group Engineering team. CHALLENGES This Project was won by Aqua Energy Group on the merit that we could supplu a complete drought relief package in a short time frame. We are proud that we could not only deliver the project in the time frame specified, but we were also able to use all Australian made products.

05 Mar, 2024

PROJECT Reagent Turnkey Dosing Station INDUSTRY Mining LOCATION Hunter Valley, NSW Australia EQUIPMENT 2x Double- sided, Custom Designed dosing pump cabinets for hazardous and Non-hazardous fluids, 1x motor Control cabinet DURATION 9 months VALUE $1 Million Aqua Energy Group were engaged to design, supply, install & commission a complete Reagent Plant to suit our clients requirements. This Project utilises two double sided pump cabinets with a mixture of hazardous–rated and standard dosing pumps to pump set amount of liquid into the thickening plant on site. These cabinets are accompanied by a customised switchboard for full operation of the units. Two large 40FT containerised Fuel storage units were supplied as part of our package, flow-monitoring, all lighting, and complete installation project. CHALLENGES Aqua Energy Group was able to navigate very strict environmental requirements and tight timeframe for the customer to get their new coal fines handling plant up and operation ASAP.

05 Mar, 2024

PROJECT M4-M5 WestConnex INDUSTRY Infrastructure LOCATION Sydney, NSW EQUIPMENT Complete turnkey deluge and hydrant suppression system DURATION 18 months VALUE $6 million DESCRIPTION Aqua Energy Group provided a complete deluge and hydrant suppression system for the WestConnex M4-M5 tunnel between Haberfield and St Peters. Our company was engaged to supply and install electric and diesel deluge assemblies along with pipeline, valving, and electrical switchgear. CHALLENGES Numerous supply chain issues were overcome. To understand transients within the system, detailed engineering was required to ensure the project was constructed to the highest standard.

By Client Care

•

21 Feb, 2024

PROJECT Pontoon Pump Station INDUSTRY Mining LOCATION Ravensworth Hunter Valley, NSW Australia EQUIPMENT Complete pontoon pump station, control panel and associated pipework. DURATION 12 months VALUE $2 Million DESCRIPTION Partnering with our client Aqua Energy Group were able to design, supply and Install Fire pump Systems and Ancillary Equipment Under an Annual Supply Agreement, Aqua Energy Group Managed everything from all civil works through to final commissioning and hand over of the project, on time and on Budget. CHALLENGES Aqua Energy Group was able to navigate very strict environmental requirements and tight timeframe with an operation large mining company to ensure their Fire Protection Codes Short Programs and Multiple Contract orders were delivered and Installed to Aqua Energy Groups High Standard. . Aqua Energy Group managed everything from all civil works through to final commissioning and hand over of the project.

By Aqua Energy Group

•

22 Mar, 2023

PROJECT Fire Protection Pumps INDUSTRY Mining/Fire LOCATION Ravensworth Hunter Valley, NSW Australia EQUIPMENT Diesel Fire Hydrant and Sprinkler Pumps, Electric Fire Hydrant and Sprinkler Pumps, Priming Jacking Pumps DURATION 12 months VALUE $2 Million Partnering with our client Aqua Energy Group were able to design, supply and Install Fire pump Systems and Ancillary Equipment Under an Annual Supply Agreement, Aqua Energy Group Managed everything from all civil works through to final commissioning and hand over of the project, on time and on Budget. CHALLENGES Aqua Energy Group was able to navigate very strict environmental requirements and tight timeframe with an operation large mining company to ensure their Fire Protection Codes Short Programs and Multiple Contract orders were delivered and Installed to Aqua Energy Groups High Standard. . Aqua Energy Group managed everything from all civil works through to final commissioning and hand over of the project.

By Aqua Energy Group

•

22 Mar, 2023

PROJECT Water Storage System INDUSTRY Municipal LOCATION Nyngan, NSW Australia EQUIPMENT An In ground water Storage System, Pipeline from storage to Bogan River, New Pumping Station, and Associated Equipment Including Power Supply. DURATION 6 months VALUE $1 Million Partnering with our client Aqua Energy Group were able to supply and Installall Electrical and Mechanical Materials, Plant and Equipment for the construction of a 700ml in ground storage facility for our clients in Nyngan, NSW. Aqua Energy Group were able to complete the final commissioning and hand over of the project, on time and on Budget. CHALLENGES Challenging Rural Location for transport and logistics,

By Aqua Energy Group

•

22 Mar, 2023

PROJECT Water Treatment Plant INDUSTRY Rail/Mining LOCATION Newcastle, NSW Australia EQUIPMENT Complete Sewer Packaged Treatment Plant. DURATION 12 Months VALUE $2 Million Following a detailed specification working with world-class construction company, Aqua Energy Group designed, supplied, and delivered a new sewer packaged treatment for the new train maintenance facility being built. CHALLENGES Ensuring complete customer satisfaction and ensuring all the strict requirements of the project were met or Exceeded.

By Aqua Energy Group

•

22 Mar, 2023

PROJECT Water transfer Pump Station INDUSTRY Mining LOCATION Midwest, NSW Australia EQUIPMENT 1x switchroom with accompanying MCC and VSD’s. 3x pump sheds with associated Pipework DURATION 6 months VALUE $1.4 Million Partnering with our client Aqua Energy Group were contracted to design and manufacture a water transfer pump Station, including a switchroom with 315kW pumps, fed by VSD’s Aqua Energy Group were able to complete the final commissioning and hand over of the project, on time and on Budget. CHALLENGES Remote, difficult to access worksite, far from Aqua Energy Group’s main office. Difficult to communicate externally due to limited phone reception.

By Aqua Energy Group

•

22 Mar, 2023

PROJECT Fire Protection Pump System INDUSTRY Mining/Fire LOCATION Lithgow, NSW, Australia EQUIPMENT Diesel Hydrant Booster, Electric Hydrant Booster, Cummins Engine DURATION 2 Months VALUE $2 Million Aqua Energy Group were contracted to create fire Pump Enclosures for a mine site in Lithgow, NSW. We designed, supplied and delivered 3x Diesel Fire Protection Systems to a number of sites throughout the company’s operations within a strict 8 week timeline. CHALLENGES Adherence to strict Mining Standards , 8 week timeframe.

By Aqua Energy Group

•

22 Mar, 2023

PROJECT Diesel Fire Pump Enclosure INDUSTRY Mining/Fire LOCATION Cobar, NSW Australia EQUIPMENT Diesel AS2941-2013 Hydrant/Sprinkler Booster Pump ( 55L/S @1200 KPA), Electric AS2941-2013 Hydrant / Sprinkler Booster Pump (55L/S @1200KPA), Jacking Pump System, Complete Base Frame DURATION 4 months VALUE $250,000 Aqua Energy Group was commissioned to complete a Diesel Fire Pump Enclosure, Complete with Muffler, Exhaust, and Rain Cap, to protect from the Elements. for a remote Mine site in Cobar, NSW Aqua Energy Group Managed everything from all civil works through to final commissioning and hand over of the project, on time and on Budget. CHALLENGES Remote Site Location for Installation.

28 Feb, 2023

PROJECT BHP/BMA Tailings storage management project INDUSTRY Mining/Infrustructure LOCATION Moranbah, QLD EQUIPMENT 2 complete pontoon pump stations, a diesel dewatering pump station, fuel pod, substations, transformers, control panels, and all associated pipework and mainfold DURATION 18 months VALUE $2 Million Aqua Energy Group successfully tended and won this complex tailing infrastructure project which included the complete design, supply and commission of all electrical and mechanical aspects of the project. The project included 2 by dual electric pontoons, access walkways, 2 by kiosk substations, all mine spec control panels and instrumentation. Aqua Energy Group successfully delivered the challenging project for BHP and provided a full Turn-Key solution that incorporated all commissioned and integration of electrical and pipework manifolds. CHALLENGES Operational Mine Site Complex Tailing Project Integration with other Contractors High End Engineered Solution

Find Us

NSW Office: 21 Kalinya Close, Cameron Park NSW 2285

QLD Office: 16 Silverton Court Paget QLD 4740

WA Office: 58 Catalano Circuit, Canning Vale WA 6155