WATER MANAGEMENT EXPERTS

Get in touch on 1800 092 210

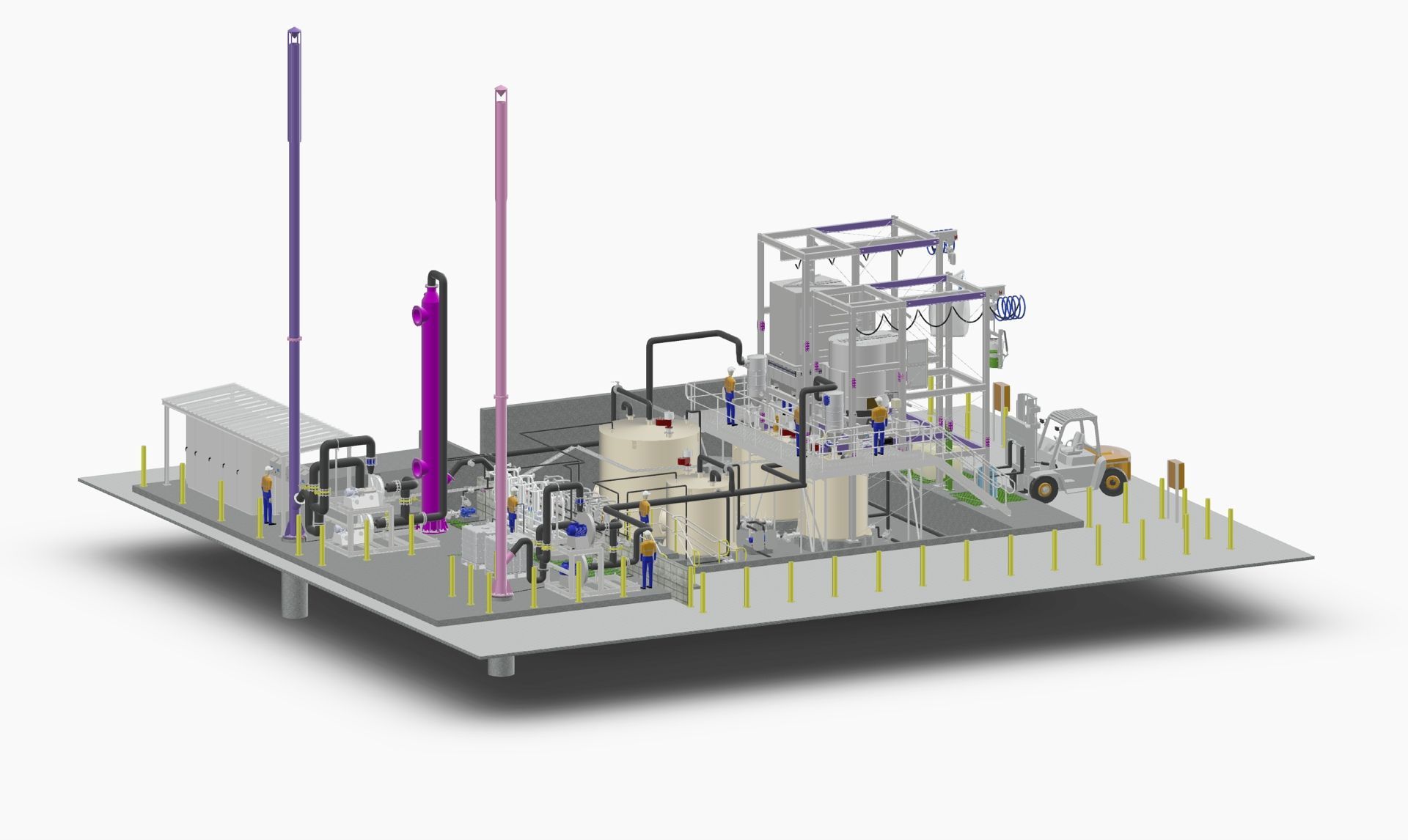

REAGENT & FLOCCULENT PLANTS

Reagent & Flocculent Plant Systems for Mining Operations

A reagent plant system allows you to perform your mining operations without being solely dependent on a tailings dam. Using a reagent plant modernises your processes, allowing you to carry on with your project in a smoother, safer and more cost effective manner. Each mine has a prep plant and a thickener tank and a Reagent plant is an add on to this process. So instead of the fines going to a tailings dam they go into a thickener tank and then get treated with reagent solution.

Fines are then collected and returned for reuse which:

- Reduces Cost

- Maximises soluble metal recovery

- Increases process throughput

Maintaining recovery, ensuring availability and sustainability while keeping costs under control is challenging. Our customised flotation solutions maximises your return on investment by enabling gains in throughput, grade and recovery, with minimised environmental impact.

The use of a Reagent or Flocculent improves the efficiency of recovering the mineral and facilitates efficient process or water recovery. Reagent plants are used wherever an additive is required to cause either a mineral or a waste product to settle out or float in the process or the water circuit. Water recovery operations often tend to lose or waste costly reagents due to the use of inefficient, ill equipped or make-shift preparation plants.

Each and every flotation operation is unique and when you choose AEG solution as your service partner, you are partnering with an organisation that is committed to understanding the precise needs of your processing plant to function smoothly and efficiently.

Features

- Efficient compact layout minimises the total footprint

- Very high process and operational availability with no loss of production

- Liquid and powder processes available

- Available in stainless steel construction for hostile environments

- Interlock protection for all critical components

Benefits

- Fully automated

- Very low operational costs and limited maintainable items

- In-house engineering and fabrication with trail pre-erection and assembly ensuring fluent site assembly with limited site work

- High quality paint specification, internally and externally for maximum practical life of equipment

Find Us

NSW Office: 21 Kalinya Close, Cameron Park NSW 2285

QLD Office: 16 Silverton Court Paget QLD 4740

WA Office: 58 Catalano Circuit, Canning Vale WA 6155